Environmental N leaching - Everest Family (Canterbury)

1 min read

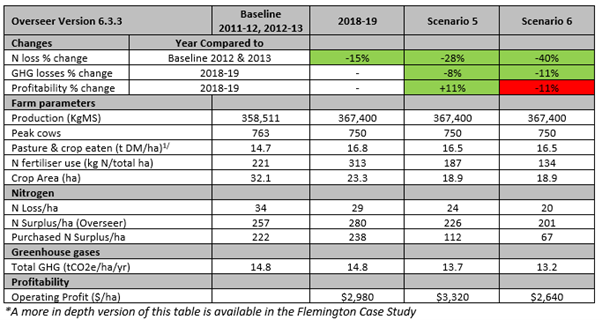

The Everest family own a farm in Longbeach, Hinds, with heavy soils leading to low N loss. They've made strides in using a low-intensity system and efficient irrigation to address greenhouse gas (GHG) emissions and N loss. Their farm, Flemington, faces challenges due to its heavy soil and high water table, but they've adopted practices that work in harmony with these conditions. The farm maintains a set cow number, utilises fodder beet, and practises effective irrigation. Even though they've efficiently reduced N loss and GHG, further improvements need more refinement. They've also explored scenarios to enhance their farm's sustainability without compromising profitability.

Flemington Farm, 10km south of Ashburton (Hinds Catchment), is 273ha of flat terrain, with a milking platform of 217ha and 38ha used for winter/feed crops and young stock. The balance, 18ha, is in trees, laneways and buildings. No cows are wintered on milking platform and young stock are grazed off from weaning.

Two options for reducing environmental footprint were modelled for this farm, from the 2018/19 season:

Structure

Owner operated

Location

Ashburton (Hinds Catchment)

Cows

750

Farm size

273ha

Farm size breakdown

217ha milking platform, 38ha winter/feed crops, 18ha trees, laneways, buildings

Irrigation

Yes

Staff

3.5 full time

“We care for the environment but need a balance between social, economic, environment – we can’t go broke individually or as an industry/country. Being involved in DairyNZ’s Selwyn/Hinds project has given us the opportunity to carefully review options. We are prepared to give things a go. For example by spreading plantain out of the fertiliser bulk spreader truck, using duals on pivots to reduce ruts, focusing on labour/time efficiency as our team only milk once a day with the automation in the dairy shed.”

– Phill Everest, Flemington Farm.

The Everest’s have chosen their low input system based on the challenges they have to work with at Flemington. Phill says that by choosing to have a lower stocking rate, they are working with rather than against the farm characteristics.

The Everest’s have invested in a centre pivot with VRI, which means irrigation efficiency can be achieved to a high degree of precision. It also allows a low application rate of effluent, which is injected into pivots over 50% of milking platform.

Flemington have adopted a low intensity system, with only 5% imported feed used on the milking platform.

Flemington’s tile drains are very effective in reducing N loss on this farm, as the N is in the whole of the soil profile and is not lost when water drains, as it is through preferential flow. N loss is by matrix flow i.e. when water flows out of the 0-60 cm root zone from the soil pores. However, if high rates of effluent are applied, (greater than 5-10 mm depth) this can lead to high loss of effluent direct to water ways through preferential flow. Flemington farm have avoided this by applying effluent at a depth of 1-2 mm via pivots.

Flemington Farm have had all their drains fenced off for at least 20 years, and have planted on the north side of the drains to provide shade to encourage biodiversity in the drains - in keeping with Mahinga Kai principles. Phill says they are currently looking into whether they can plant the south side of the drains in a way which allows them to be maintained as needed.

Flemington in the 2018/19 season produced a total of 14.8 t CO₂ equivalent/ha/yr, and 11 kg CO₂ eq/kgMS. Phill says while there is no one silver bullet available to dramatically reduce their GHG losses, there are a number of small practices they can adopt now that will make a difference. Flemington have implemented a number of these, and have had a case study done to look at future options.

Flemington were a case study farm in the Greenhouse Gas project, and six scenarios were modelled for Greenhouse Gas reduction in Overseer and Farmax. Of these scenarios, the Everests chose to focus on Scenario 5 and 6, as described below.

The main opportunity for the Everest’s to drop N loss further is to reduce their N surplus, as they have already optimised their irrigation efficiency. Scenarios 5 and 6 show that there is potential to drop from their Baseline by 28% and 40% respectively, mostly by reducing their N surplus.

Scenario 5 improves the profitability of the farm by 11%, while scenario 6 reduces profitability due to the expense of bringing in the barley to replace the pasture not grown. GHG outputs are improved in both cases, with a drop of 8% and 11% - this gain comes predominantly from the reduction in N²O and CO₂ from lowered N fertiliser use.

| Changes | Year compared to | 2018/2019 | Scenario 1 | Scenario 2 |

| N leaching | Baseline 2012 & 2013 | -15% | -28% | -40% |

| GHG losses | 2018-19 | - | -8% | -11% |

| Profitability | 2018-19 | - | +11% | -11% |

Now’s the perfect time to check in, plan, and set up for a strong season. We’ve pulled together smart tips and tools to help you stay ahead all winter long.

Whether you prefer to read, listen, or download handy guides, we’ve got you covered with trusted tools to support your journey every step of the way.