Herringbone entry & exit

2 min read

The page covers the essential design considerations for dairy entries and exits to ensure efficiency and cow welfare. It highlights the need for safe, reliable footing, a controlled slope at the entrance, and proper lighting conditions. Additionally, exits should be designed for easy drafting and quick, safe cow movement, with specific guidelines for exit paths, lanes, and gates. Attention to these details will improve cow flow and milking efficiency, reduce injuries, and make the overall process more productive and humane for your dairy farm.

The connection between the yard and the inside of the dairy should be designed to encourage cows to enter. Poorly designed entries will have a huge impact on cow flow and milking efficiency and may affect cow welfare.

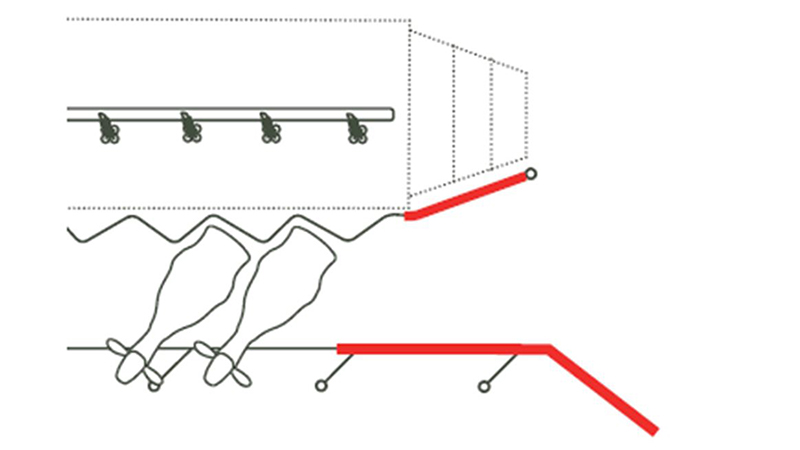

Lead in rail height

Have a lead in rail so 2-4 cows can line up facing forwards before the start of the milking bails.

Fit a rotating back rail to hold last cow in place.

Scabbling or grooving concrete can help traction and stability - make grooves consistent with drainage direction.

A diamond pattern with groove size 12mm wide and 12mm deep on 75mm centres, provides more traction than simple parallel grooves.

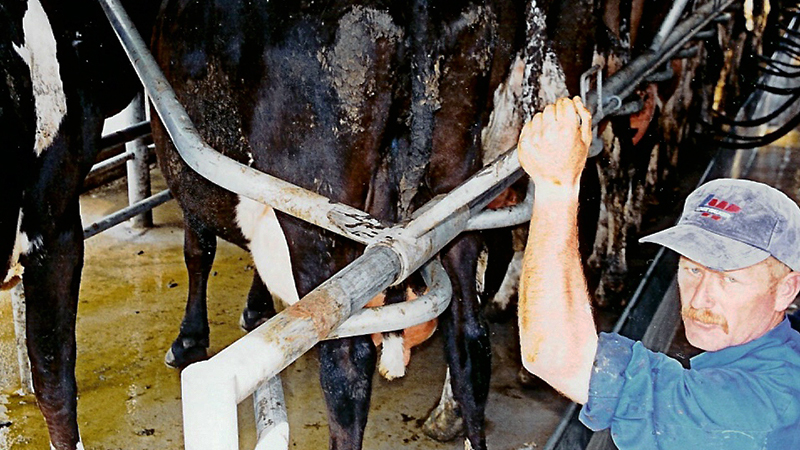

Avoid places where cows can hurt themselves, like protruding pipes and edges. Pipework should be flush across cow contact surfaces.

Skylights combined with natural lighting can even out light levels. Consider installing translucent polycarbonate roofing and/or walls.

Avoid places where cows can hurt themselves. Image shows a protruding pipe protected by deflector.

Exit races should be designed to enable easy drafting and ensure cows can leave the platform quickly and safely.

Getting your exit design right increases work efficiency and reduces injuries.

When designing an exit race, it’s important to consider:

In herringbones, cows entering the dairy should be able to follow directly behind those leaving, reducing dead time in the milking routine.

When using gates, the milker must have good control over cow movement and be able to intercept any cow in a single file line. Be aware that almost all exit gates have pinch and crush points.

A good exit gate should:

Steps are preferable to ramps.

Scissor exit gate with sufficient clearance.

Now’s the perfect time to check in, plan, and set up for a strong season. We’ve pulled together smart tips and tools to help you stay ahead all winter long.

Whether you prefer to read, listen, or download handy guides, we’ve got you covered with trusted tools to support your journey every step of the way.