Transporting Bobby Calves

9 min read

Prioritising the health of bobby calves makes transporting them more efficient. Additionally, they must meet requirements for transportation before leaving the farm to keep them comfortable and healthy. You can keep them safe by following bobby calf loading facility guidelines and design options that consider their health and safety. This helps to improve on-farm biosecurity by reducing the risk of exposure to pests, weeds and disease.

Animal welfare is at the heart of any good farming business. Our responsibility for the wellbeing of stock starts at birth and continues beyond the farm gate.

Calves must be fit for transport before they leave the farm.

8 things calves need in order to be fit for transport:

Watch the video and learn how to check if a calf is fit for transport.

Regardless of their purpose, all calves must be treated with care and respect, kept in a healthy and safe environment.

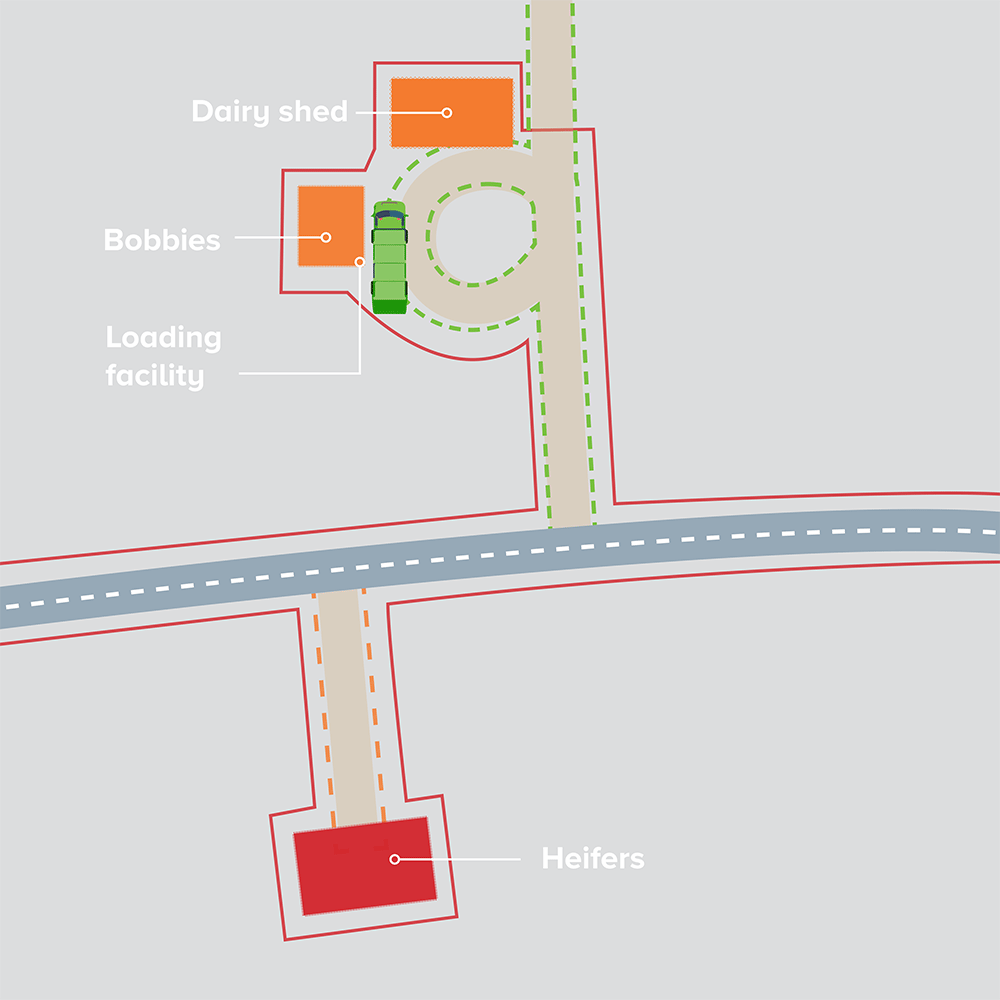

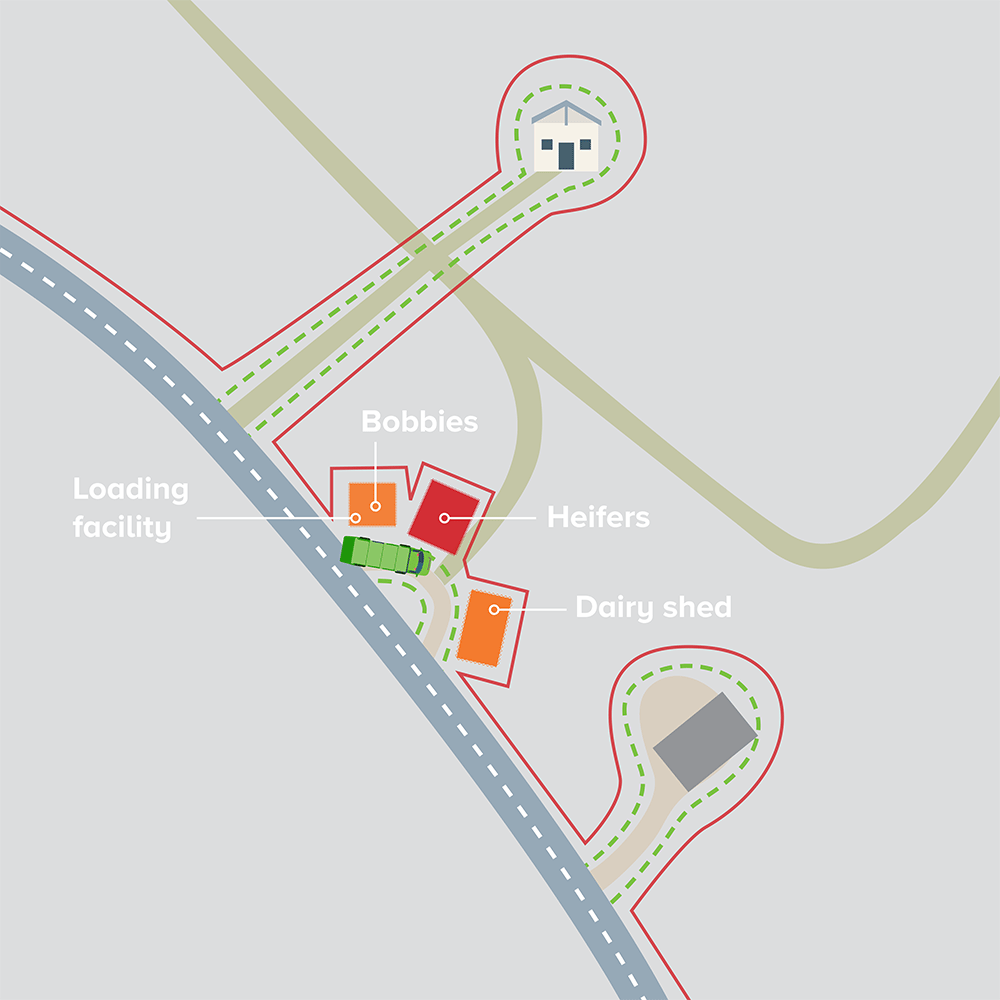

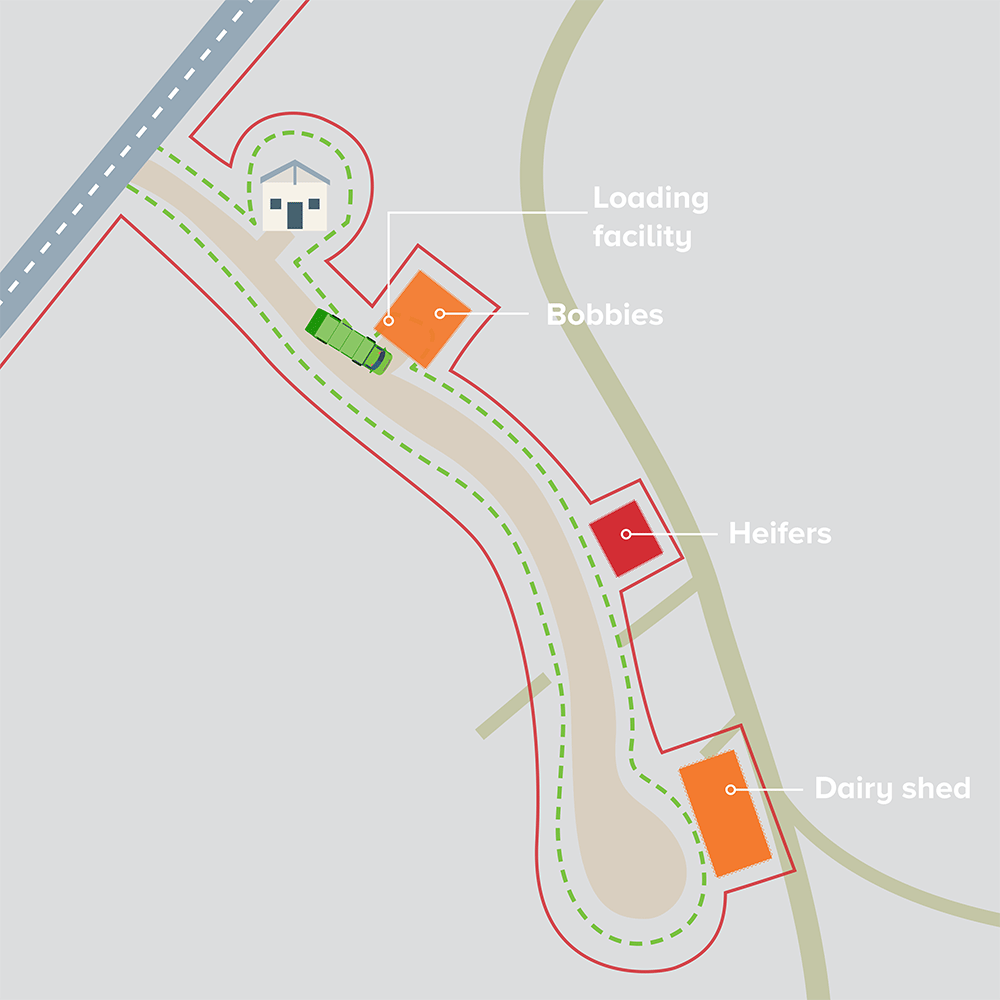

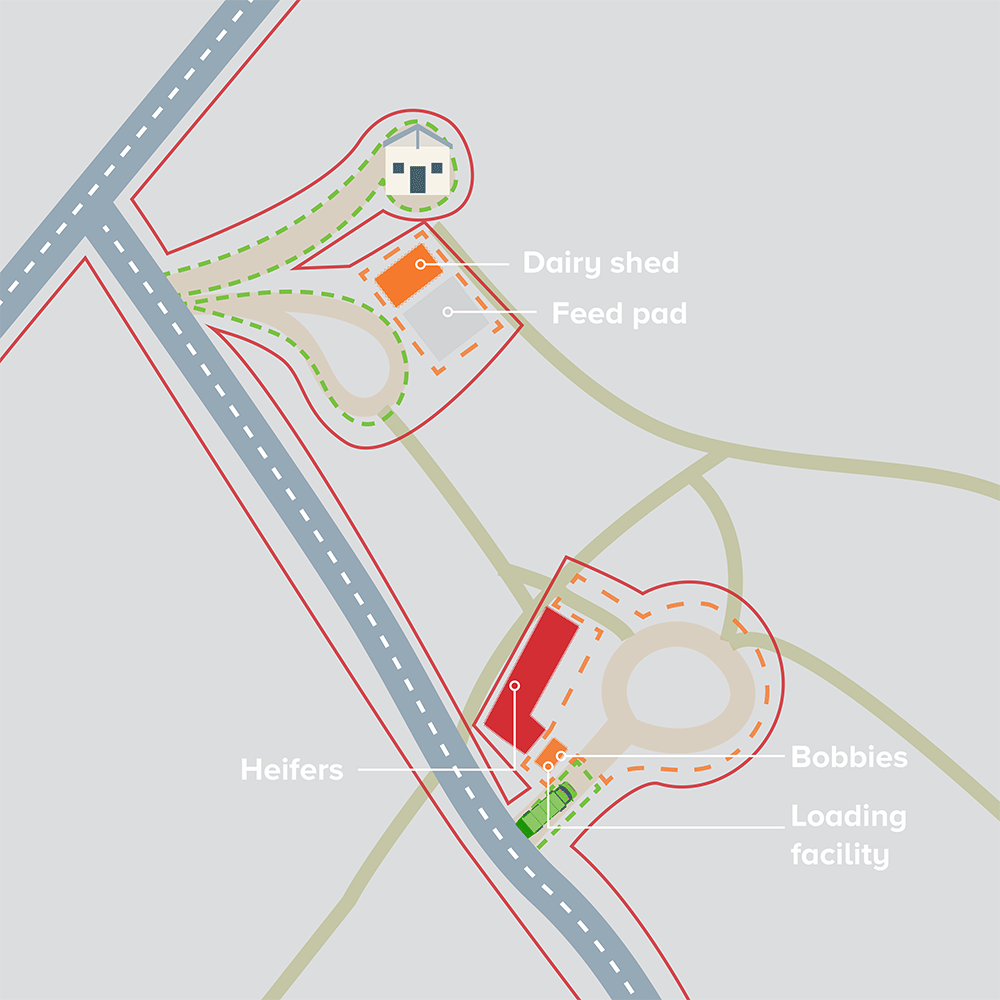

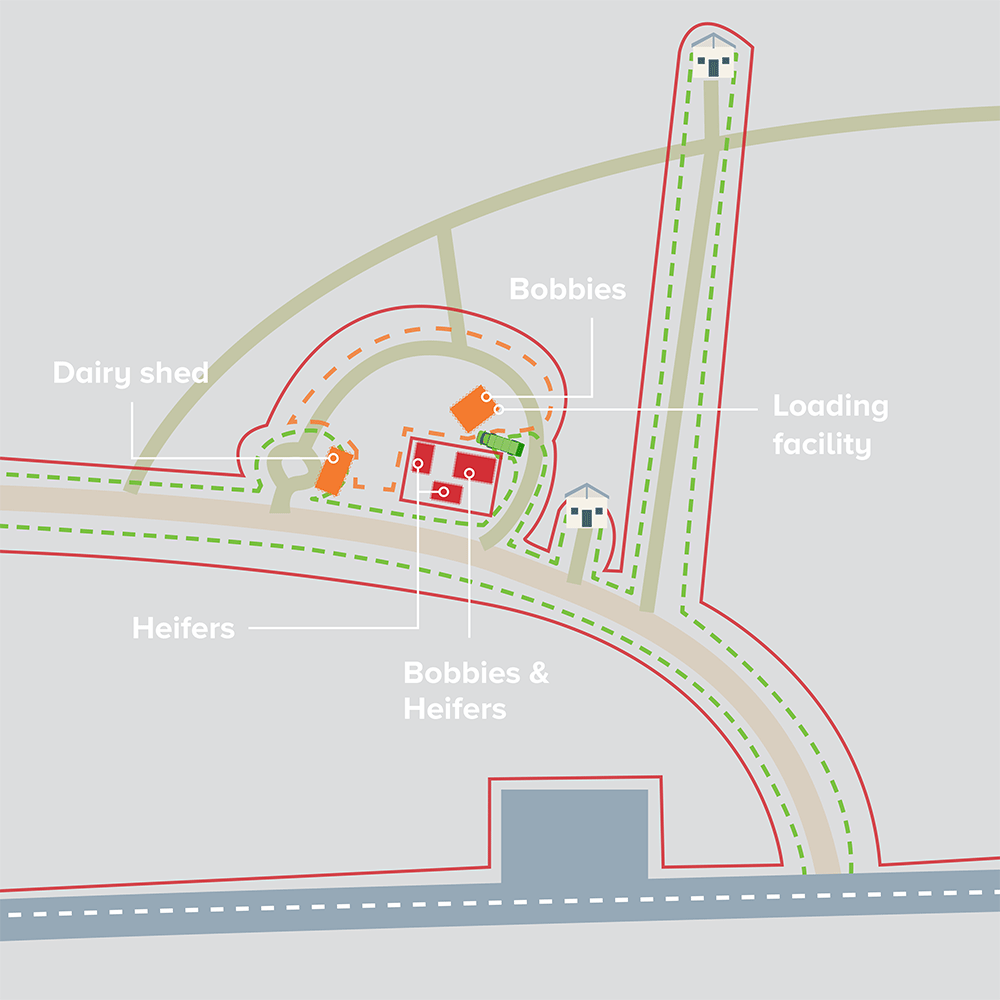

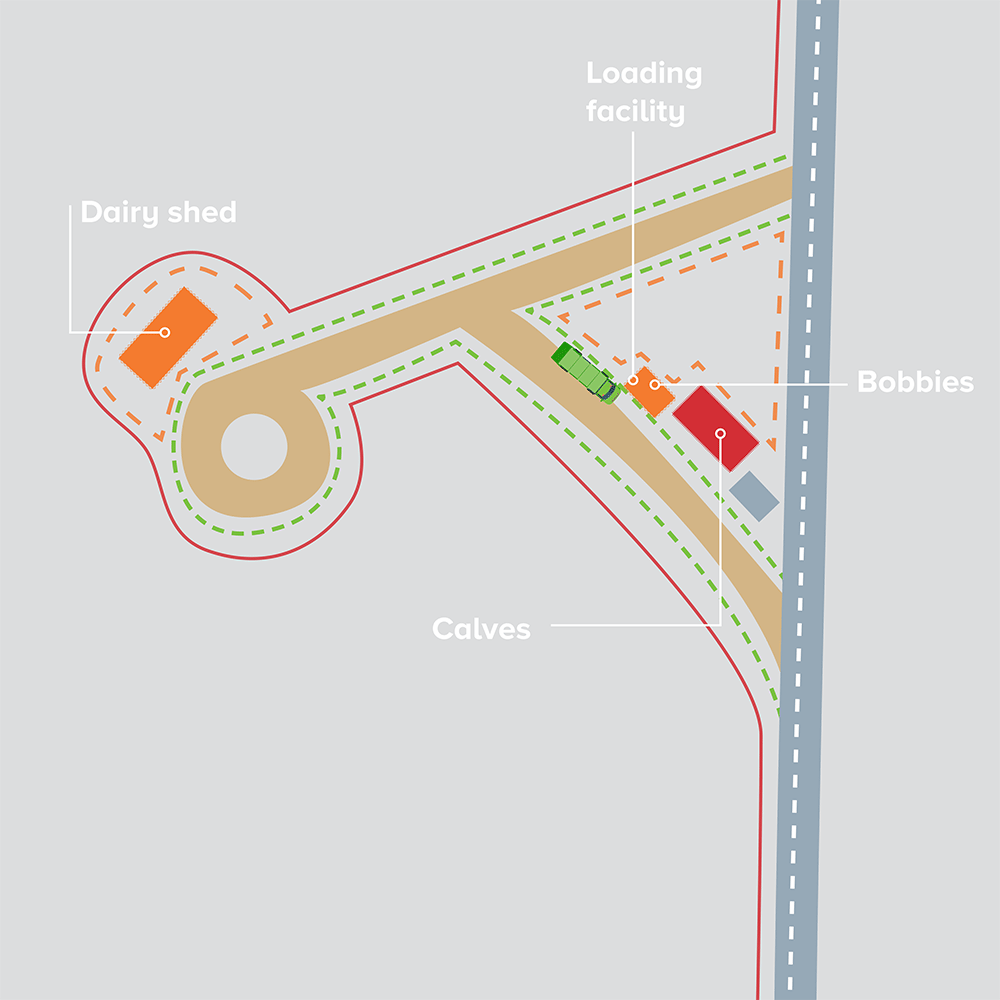

Whenever calves leave the farm on a truck, you want to work with your transporter and make their job as easy as possible. This will help to ensure that your calves are treated with care. Use the red, orange, green system to map out zones on your farm.

General rules for the red, orange, green zones:

Red: No go areas for visitors, tankers, livestock trucks (i.e paddocks and heifer rearing sheds). Red zones can only be entered after carrying out visitor biosecurity requirements.

Orange: Areas that have a mix of cows, farm staff, visitors and equipment (i.e. the milking shed and bobby calf sheds).

Green: Areas that have unrestricted access to visitors, their vehicles, tankers and livestock trucks but restricted access by cows (I.e. the milk tanker track, access tracks to houses on farm, bobby calf and slink pick up points).

The bobby calf truck should remain in the green zone whilst on farm. When loading bobby calves, minimise crossover between the truck, drivers, and the inside of your bobby calf sheds.

Here are some examples of how to zone your farm.

TIP: Have separate equipment (feeders, boots, overalls) for the heifer shed and bobby shed, or disinfect between each use.

The Code of Practice for design and operation of farm dairies (NZCP1) has no conditions about loading facilities and proximity of the farm dairy.

Calves must not be housed within 20m of the farm dairy, however, you can temporarily hold calves within 20m of the farm dairy before pick-up (e.g. on the same day while waiting for collection, with time of holding minimised).

All standards regarding surfaces and drainage apply, as do requirements for shelter. If you’re taking this approach, the area where calves are held must be maintained in a suitably hygienic state and must be cleaned immediately after the calves have been collected.

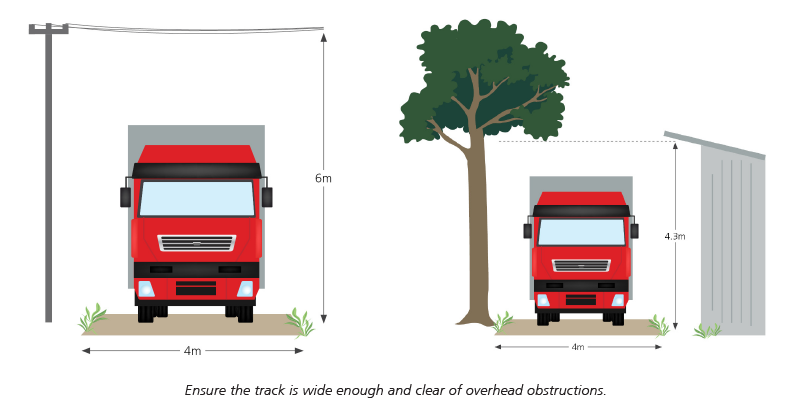

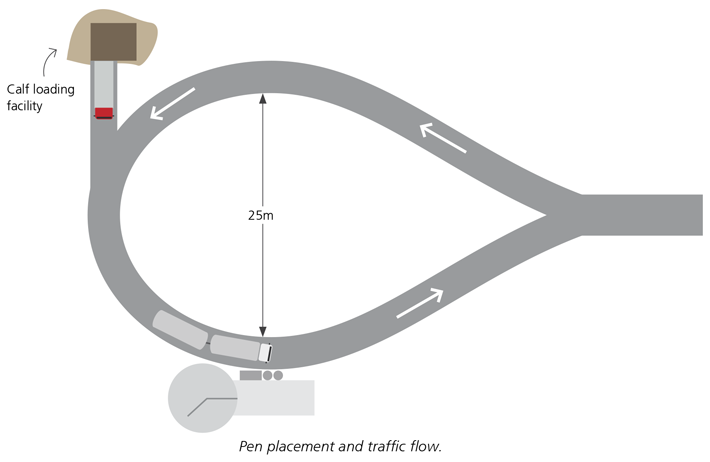

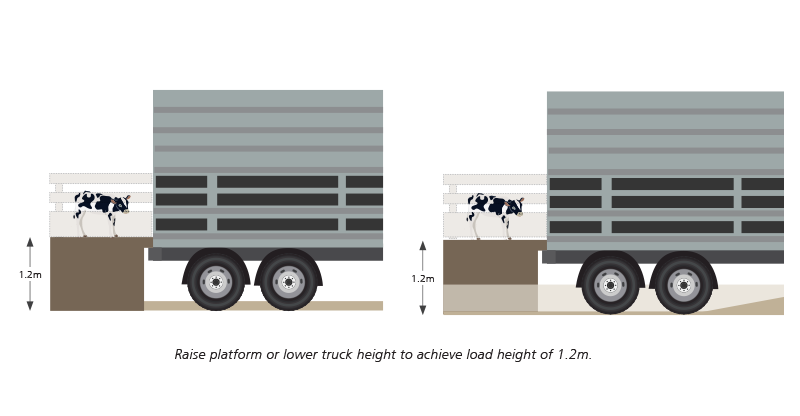

Holding and loading facilities should be designed and constructed so that calves are able to walk directly from the loading facility onto the truck. Health and safety regulations mean that it’s no longer acceptable for transporters to repeatedly lift calves from the ground to truck deck height. Raised loading facilities will also help to improve the wellbeing of calves being transported.

Consider the environment of where your facility is located as the design will depend on where the platform is situated (e.g. wind direction, exposure and rain fall, or additional windbreakers may be required to stop calves from getting wet).

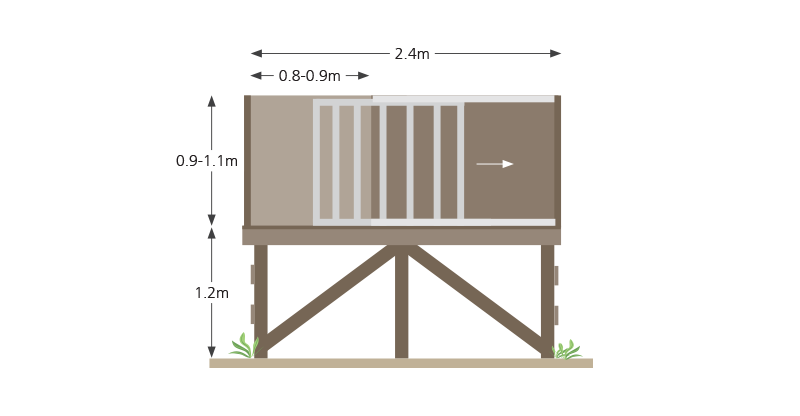

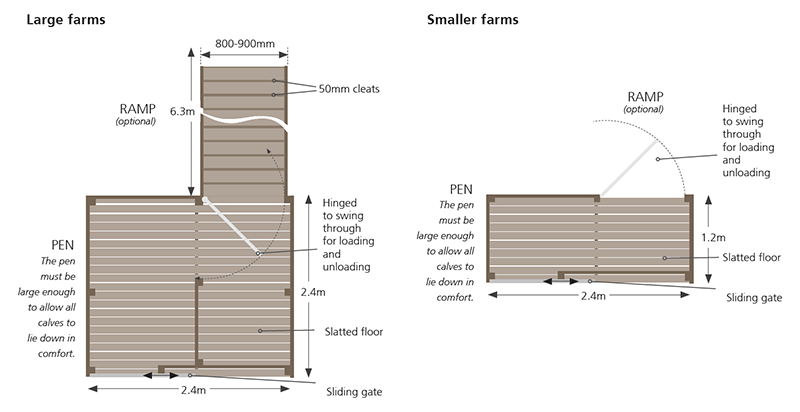

Platform: level, with a load height of 1200mm.

Loading doorway: a width of 800 to 900mm.

Pens side height:

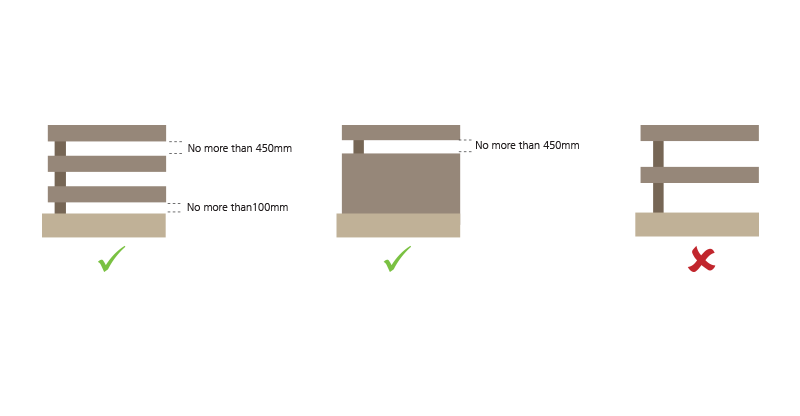

a. 900mm to 1100mm solid construction (ply or closely spaced rails to provide shelter, if rails are used, spacing must not create a hazard for calf heads/legs).

b. If using rails, the gap between the bottom rail and floor should be no more than 100mm.

c. If using a top rail, the gap between the top rail and the rail below or solid side must be no more than 450mm.

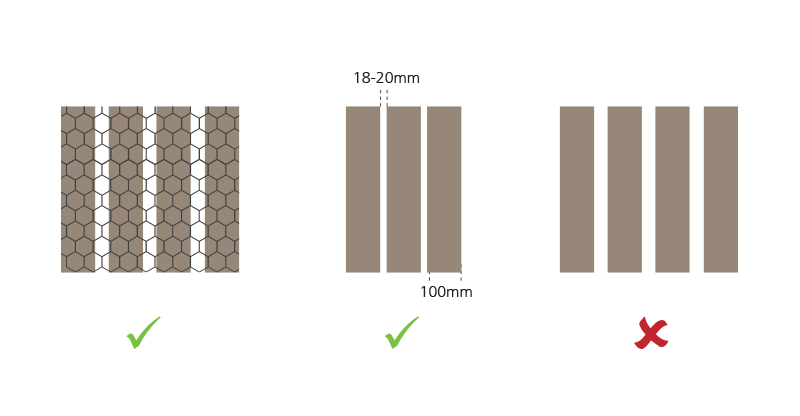

Flooring: solid construction, free-draining non-slip surface and slatted flooring is ideal. The use of non-slip rubber matting or geogrid stretched and secured over a timber slated floor can add grip and prevent hooves from being caught in floor slats. A gap of 15 to 20mm between slats is recommended.

Total size: large enough to allow all calves to lie down in comfort. Pen size depends on farm size and calf numbers. 2.4m x 2.4m is considered suitable for most farms as this size pen will comfortably hold 15 to 20 calves depending on calf breed/size. Smaller farms could reduce the size to 2.4m x 1.2m. Larger farms may need multiple pens. For a large pen, use a divider/backing gate to manage larger numbers of calves and to help confine the calves during the loading process.

Space allowance for calf breeds

| Breed | Area/calf | Calves/m³ | 2.4m x 2.4m | 2.4m x 1.2m |

| Jerseys/Cross breed | 0.3 - 0.35 | 2.9 - 3.3 | 17 - 20 calves | Up to 10 calves |

| Holstein/Friesian | 0.35 - 0.4 | 2.5 - 2.9 | 15 - 17 calves | Up to 8 calves |

Construction and hardware: covered pens and loading facilities need to be safely accessible for people and safe for calves, avoid sharp edges, trip hazards, protrusions, etc.

Water: calves must have fresh water available in the pen.

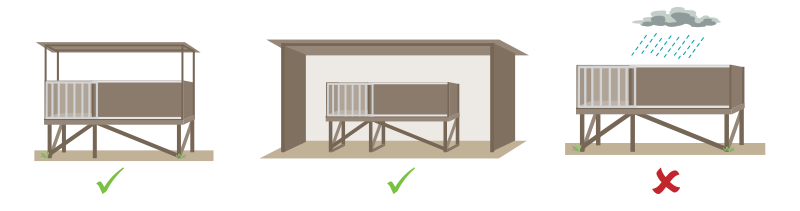

Shelter: calves that have been removed from their mothers must be provided with shelter from weather likely to affect their welfare. The loading facility should either be:

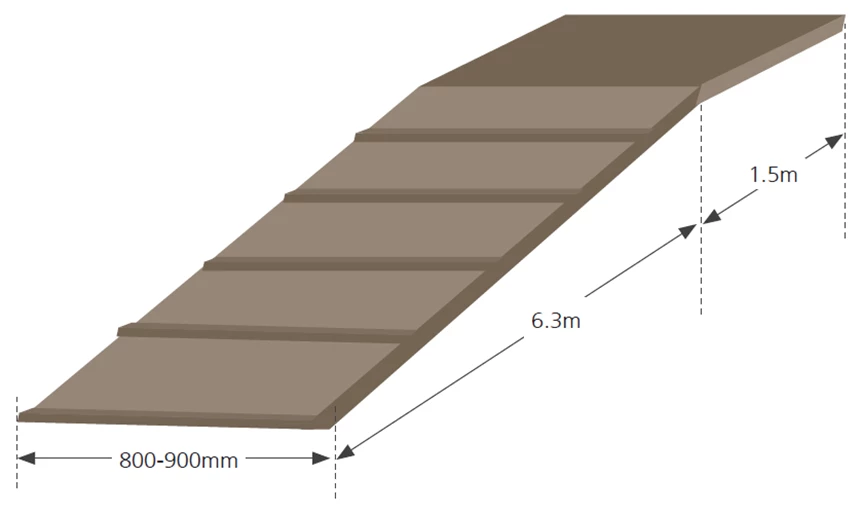

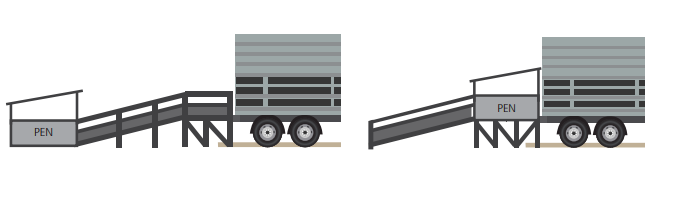

Ramps can be used to load calves either into a raised holding pen before pick-up (recommended) or be loaded out of a ground level pen onto the truck.

Check with your local council to see if your proposed facility needs building consent or whether it is exempt under Schedule 1 of the Building Act.

Building consent is not normally required if it is a temporary, moveable or detached structure or is a permanent structure that:

For more information on building work that does not require a building consent you can go to building.govt.nz.

If you want to construct a floor height higher than 1m to achieve the desired loading height of 1200mm, you may need to apply for a building exemption. Guidelines on the consent process can be found at building.govt.nz.

Regardless of whether consent is required or not, the structure must be safe and must comply with the building code.

Identified hazards should be addressed through good design rather than management controls.

| Potential hazard | Solution to hazard |

| Crush point between the facility and reversing truck. | Create a no-go zone between the truck and the ramp. |

| Portable ramps/holding pen moving backwards or becoming unstable when the truck reverses into it. | Create a no go zone behind the ramp. |

| Poor alignment between the facility creating a gap. | Use a solid hinged flap or extension to cover the gap between the loading facility and the truck. Fit a compressible buffer at the truck/facility interface. |

| Consider health and safety requirements when planning and reviewing access to the holding facility. | Stairs with handrails are much safer than fixed ladders. Portable ladders should be avoided. |

Use existing topography and dig into a bank or create an earth mound against a wooden retaining wall, providing a face to load off. Depending on existing topography and available drainage, it may be possible to reduce the necessary loading height by digging down to lower the deck height of the truck so that the access point is lower.

Form sides and loading face using treated posts and timber rails, then create the ramp by filling between the timber sides using packed earth.

Adapting an existing woolshed or utilising a disused tanker stand may provide a low-cost option to achieve the correct loading height.

Typically loading ramps for cows are not suitable for calves as they may be too steep or have wide gaps in the sides, which can become trap hazards for calves. Attaching plywood with cable ties to create a solid-sided ramp may be an affordable option. You might have to create a sheltered holding area as well.

You can get a commercial holding platform from a timber merchant or a farm supply store in some regions. They offer a variety of kit-sets, typically moveable and made of timber on skids. Not all kit-set platforms are supplied with a roof, so you may need to place them within an existing structure to provide sufficient shelter from extreme weather conditions. Alternatively, build your own using the specifications outlined above.

If you are purchasing a commercially produced holding pen, check that it has been designed to meet the New Zealand Building Code requirements and that Producer Statements are available.

Another option for raised platforms is a ramp that can be incorporated into the design, so you will not have to lift calves into the holding area.

Using a tractor-mounted carry tray may also be an option on some farms.

The design of your facility should depend on where the platform is situated, wind direction, exposure and rain fall, additional windbreakers may be required to stop calves from getting wet.

Now’s the perfect time to check in, plan, and set up for a strong season. We’ve pulled together smart tips and tools to help you stay ahead all winter long.

Whether you prefer to read, listen, or download handy guides, we’ve got you covered with trusted tools to support your journey every step of the way.