Maintenance

2 min read

Failures of pumps and irrigation equipment on your dairy farm can lead to wasted time, limited pasture growth, and stress. The page highlights the importance of regular checks and ongoing maintenance to prevent these issues. Having a list of weekly, monthly, and annual tasks helps keep maintenance up-to-date. The page also offers guidance on essential procedures for most irrigation systems and emphasises the importance of fixing any issues quickly to prevent loss of pasture production or nutrients. If you're installing a new pump, make sure to get specifications and a commissioning report from the supplier.

Failures of pumps and irrigation equipment during the season can waste a lot of time, restrict pasture growth and create stress.

Regular equipment checks and ongoing maintenance is vital in preventing breakdowns and reducing the chance of serious damage. Having a weekly or monthly and annual task list for irrigation maintenance, where you can check tasks off easily, ensures maintenance is kept up-to-date.

Below is a summary of some essential maintenance procedures for most irrigation systems. For more detail specific to your system, contact the service provider. If you install a new pump, ensure the supplier provides the specifications and a pump commissioning report. This will serve as benchmarks for future checks.

Print off and fill out ‘your farm’s irrigation information’ template and hang it at the shed for staff to refer to.

Before the irrigation season starts

IrrigationNZ has pre-season checklists and performance assessments for a range of irrigation systems. To find these checklists, click here.

First irrigation

At the pump:

At the irrigator:

During irrigation season

At the pump

At the irrigator

At the end of the irrigation season

At the pump:

At the irrigator:

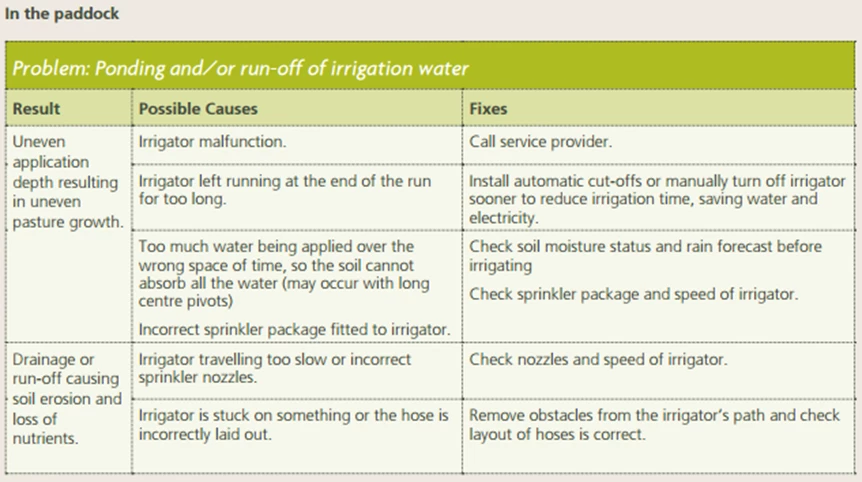

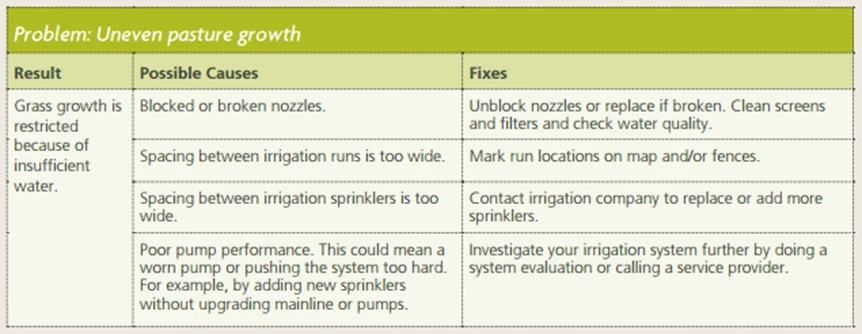

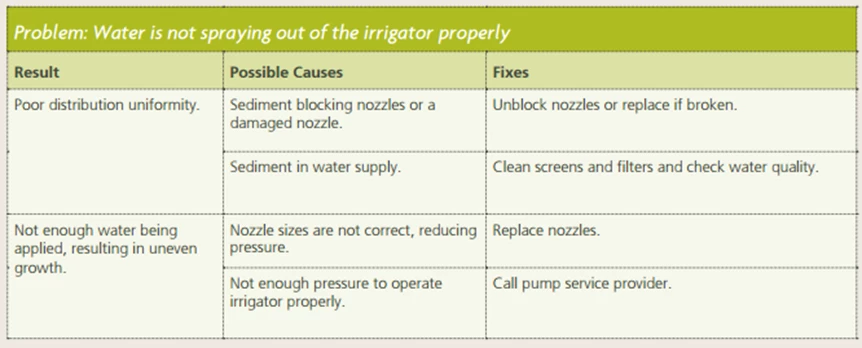

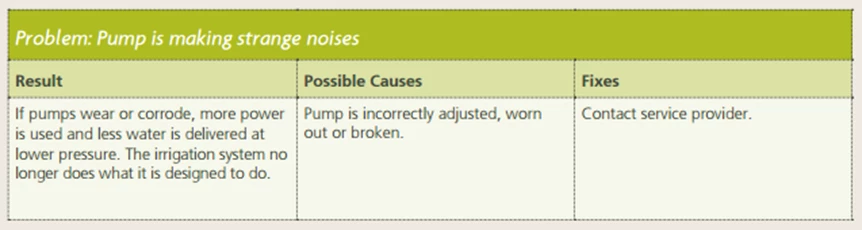

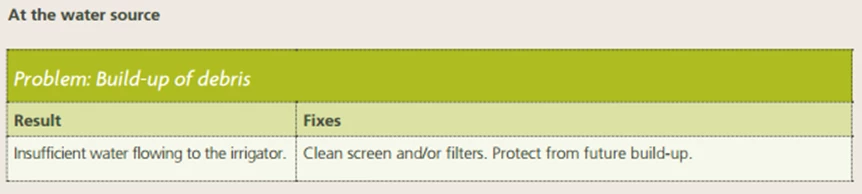

Problems which occur with irrigation can range from minor issues which take time to fix, through to major problems that cost time, money and loss of pasture production (from delayed irrigation) or loss of nutrients (through over watering). It is important that any problem is fixed quickly and the cause identified to stop it happening again.

Below is a summary of common irrigation problems.

Now’s the perfect time to check in, plan, and set up for a strong season. We’ve pulled together smart tips and tools to help you stay ahead all winter long.

Whether you prefer to read, listen, or download handy guides, we’ve got you covered with trusted tools to support your journey every step of the way.