Rotary entry & exit

2 min read

Dairy exit and entry races refer to the design of the pathways that lead cows in and out of the milking platform. Good exit and entry design can speed up the milking process and reduce cow injuries. For exits, signals like a bar in the rump rail, water sprays, or compressed air can guide the cows, and the exit area should be spacious with rubber matting for comfort. For entries, ensure safe footing and a well-lit area, avoiding sharp or dark shadows, and consider rubber matting and appropriate pipe placement. Both the design elements can significantly impact efficiency and animal welfare on your farm.

Improve cow flow and milking efficiency by ensuring the connection between the yard and inside of the dairy is well designed.

Poorly designed entries can have a negative impact on cow welfare and cause stress for handlers.

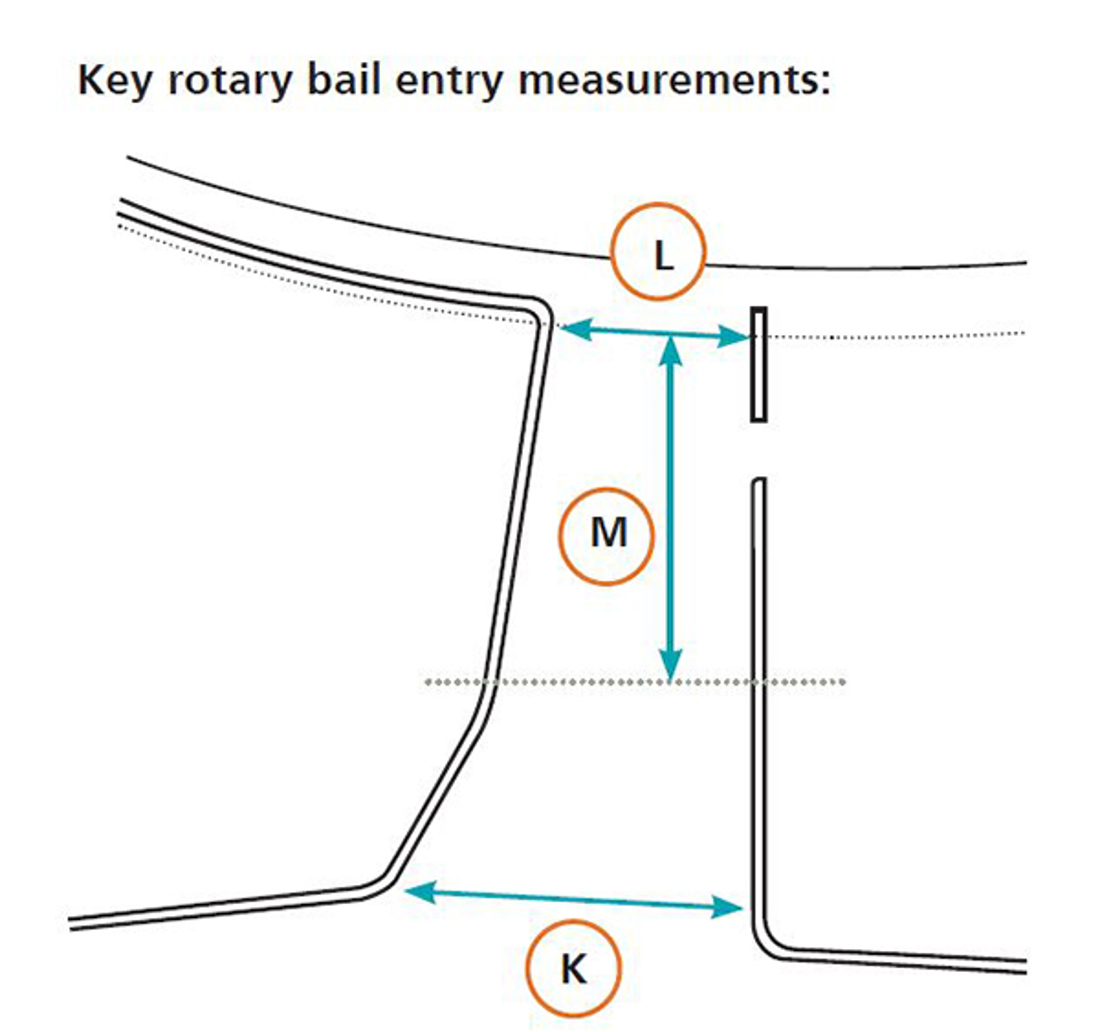

Although not essential, a single file entry race can help cow flow. Less dominant cows are more likely to enter of their own accord as they cannot be bullied by other cows. When designing an entry race, make sure of the following:

The entry race should be at least one cow in length (approx. 2m). Two cow lengths (3m) are beneficial if you need to slow cows down for electronic ID systems or feeding in-bail.

This allows the next cows in from the yard to encourage the cows in front onto the platform.

This reduces slippery surfaces - there can be considerable pushing in the entry area.

Pipework should be flush across cow contact surfaces (horizontal pipes on the cow-side of vertical posts for example).

Dairy exit races have a big impact on how quickly cows leave the milking platform, and how easily they can be drafted.

Reduce the amount of time milkers spend encouraging cows out of the dairy and reduce cow injuries with good exit design.

Cows not exiting the platform once finished milking negatively affect efficiency.

Good example of a rotary exit.

Now’s the perfect time to check in, plan, and set up for a strong season. We’ve pulled together smart tips and tools to help you stay ahead all winter long.

Whether you prefer to read, listen, or download handy guides, we’ve got you covered with trusted tools to support your journey every step of the way.