Flexible Milking, Daryl and Karyn Johnson (Taranaki)

6 min read

Taranaki farmers Daryl and Karyn Johnson have adopted a 3-in-2 milking routine, milking their cows three times every two days. This method has enhanced herd health, improved staff well-being, and boosted farm profitability. Key achievements include a drop in the not-in-calf rate from 20% to 13%, maintaining a healthier cow body condition, and reducing somatic cell count. Their team has also benefitted, experiencing reduced working hours, thus promoting a better work-life balance. Despite initial challenges in grazing management, adjusting their system led to better results. The Johnsons find this approach aligns with evolving welfare and environmental expectations in farming.

Three, two, done

For most people, three doesn’t go into two. But for Taranaki farmers Daryl and Karyn Johnson, that formula has proven to be a winner, helping them improve herd health, staff wellbeing and farm profitability

Structure

Owner-operators

Location

Stratford, Taranaki

Cows

460 crossbred cows

Farm Size

160ha

Production

398kg MS/cow

Imported Feed

540kg DM/cow

Irrigation

No

Staff

3 full time equivalents (153 cows/FTE)

Roster

12-2

Milking Regime

Full season 3-in-2 since 19/20 season start

Pilot farm flexible milking times

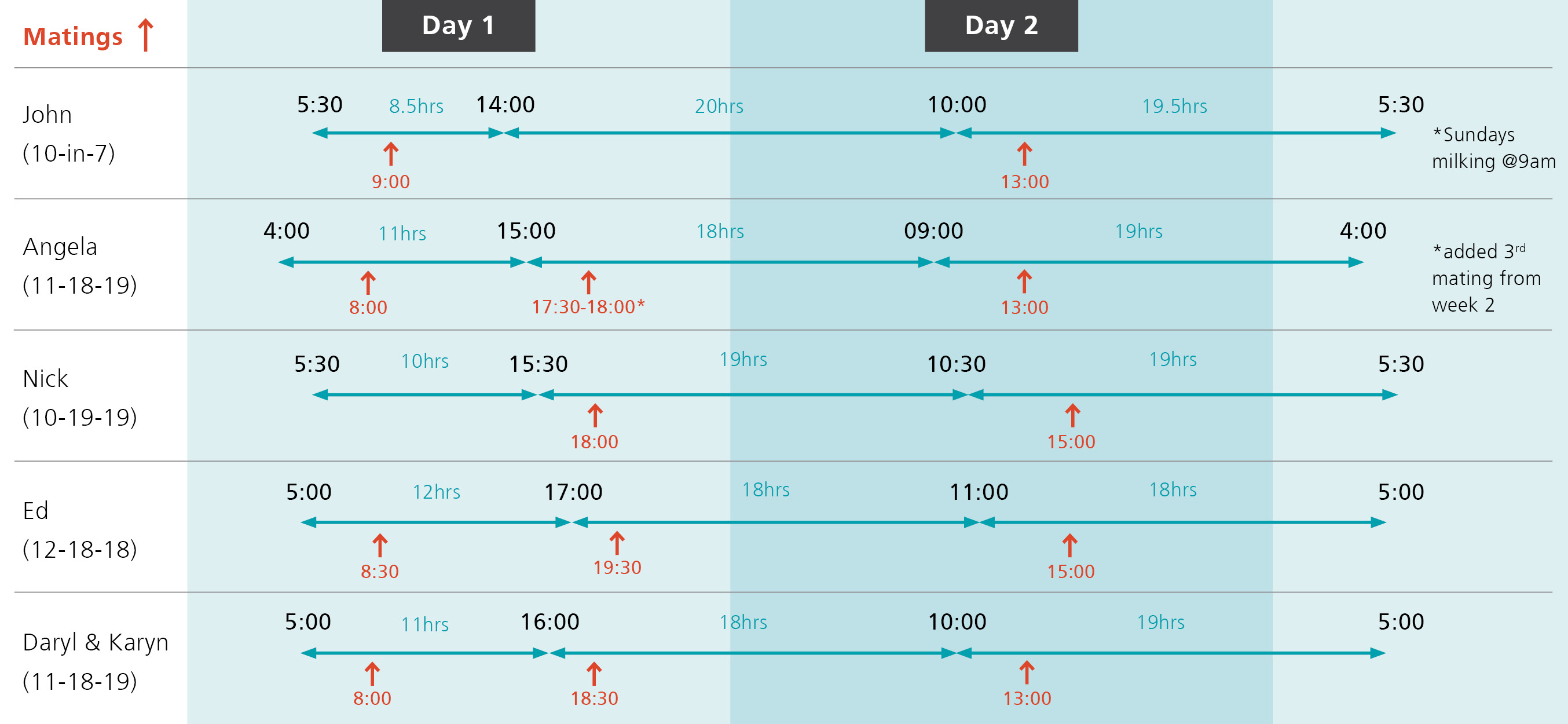

Daryl and Karyn Johnson are heading into their third full season (21/22) of milking three times every two days (3-in-2), at hours they’ve fine-tuned over their first two seasons.

They employ two full-time staff on their 460-cow, 160ha property near Stratford. Like farmers everywhere, they’ve been increasingly conscious of the need to keep their good staff and make the operation as “people-friendly” as possible.

“Young people today are seeking a work-life balance. They’re not prepared to go sunrise to sunset with few breaks and little time off, like it was for us,” says Daryl.

The couple had used the 3-in-2 routine for the second half of lactation for three years, before going full-season 3-in-2.

“We really enjoyed the part-season. For us, it was less risk than going once-a-day, with the possibility of losing production, and impact upon our bulk somatic cell count (SCC),” says Daryl.

The Johnsons were motivated to use 3-in-2 for the second half of the season to give their staff, Michael Webby and Rebecca Sturgeon, more flexibility over the summer-autumn period. However, the move to full season was prompted by rising concerns over their herd’s health and performance.

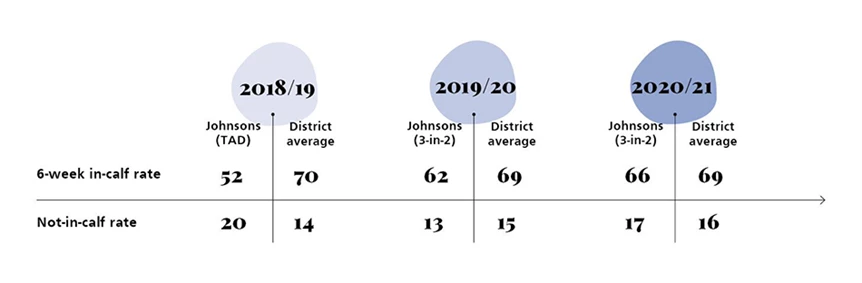

“The main problem we wanted to address was the herd’s not-in-calf rate, which had climbed to 20% and just was not sustainable,” says Daryl.

“Heifers were losing over 100kg in bodyweight post-calving, and lameness was an issue given the up and down nature of the farm and walking distance.”

Running a tight System 2 operation, they were loath to have to increase costs by bringing in more supplement over spring or having to use CIDRs to deal with cycling issues.

“We’d come through a period of farm expansion successfully by keeping costs tight. That’s got us through most challenges, and we did not want to change that,” says Karyn.

“To us, 3-in-2 would minimise a financial cost. We were also conscious our staff had been working long hours over spring, and we didn’t feel that was sustainable either.”

Shifting to a flexible milking routine delivered on their hoped-for improvement in herd repro performance, with a major drop in not-in-calf rates, from 20% to 13%. They attribute that to the 25% less walking, resulting in the cows conserving more energy.

Daryl estimates the herd, on average, held onto 0.4 of a body condition score, which they’d normally have lost over that stressful calving-mating period.

“And lameness really reduced,” says Karyn. “Our farm has a lot of hills and the pressure on cows’ feet, especially over spring, is always an issue. That really fell away.”

SCC did not increase, and Daryl’s fear of more spring mastitis proved unfounded. The average bulk SCC for the herd has in fact dropped from its longer-term average of only 125,000 to an even more comfortable 110,000.

When Daryl and Karyn first started using 3-in-2, their initial routine was a 5am milking and 4.30pm milking on day one, then a 10am milking on day two.

The team enjoyed the change from the usual grinding springtime routine, having the chance for a sleep-in on day two, with calves fed and cows and calves drafted and collected prior to the 10am milking.

“You just had to get your head around the shift in routine. But on that second day, you have the time to tend to jobs – you don’t find yourself having to drop everything for that afternoon milking,” says Daryl.

They’ve shifted the afternoon milking time over the past two seasons, from a 4.30pm start in year one to 4pm last season. It’ll be brought forward again to 3pm this year (21/22) (10-19-19 interval), making it a more family-friendly finish time for one staff member.

Refining the system

Karyn says, when they committed to the routine two years ago, she fully expected they’d produce less over their peak but have no production slide after Christmas.

“But in year one we experienced a drop in production at the peak that continued beyond Christmas.”

Production fell to 162,000kg MS, against the farm’s longer-term average on twice a-day milking of 176,500kg MS, and Karyn puts this down to how they were allocating paddocks (and they were also milking 5.4% fewer cows).

“In that first year, we were just working on current paddock size for feed allocation.

“The herd ended up short on the longer gap between milkings, our round ran too slow, and it also impacted on the quality of feed. In addition, we tended to keep making more hay than silage, with the paddocks out of the round for longer later in the season as a result.”

In year two, they took a step back and reset their grazing rotation, working on a revamped spring rotation planner to calculate what the cows needed hourly, rather than daily.

“It turned out the herd needed more feed in that 19-hour gap than they were getting. Suddenly, we found the system worked better for us and the herd,” says Karyn.

“With multiple paddock sizes, it was almost impossible to allocate the correct amount of feed required in a single paddock. So, we worked on incorporating more paddocks, or parts thereof, to meet the feed requirement.

“Making more pit and baled silage instead of hay meant we had paddocks back in the rotation quicker, with better quality grass in the late summer period.”

The rotation adjustment led to the farm’s second-highest production result last season: 183,000kg MS. This even surpassed Karyn’s initial ambitious goal of 180,000kg MS.

Unfortunately, the solid reduction in the herd’s not-in-calf rate achieved in year one wasn’t repeated last season, pushing back up to 17%.

“We’ve tried to determine why but do know many herds in this district experienced a lift in not-in-calf rate last season, and it may have come down to poorer-quality feed over spring,” says Karyn.

However, they’ve managed to lift and hold the herd’s 6-week in-calf rate, now at 66%, compared to 52% in the 2018/19 season.

“This represents another 30 to 40 cows in calf early, which is significant for us,” says Karyn.

The couple have also seen major farm costs savings.

“Fuel and power are down $5000 each; animal health is down $10,000. We used 140t less meal with the herd being in the shed less often. By year two, our overall costs were $2.82kg MS (excluding wages) or $3.39 including wages, an overall 5% decrease to our twice-a-day system FWE.

Despite the change in routine, the Johnsons haven't downsized their team. The two staff members had some initial concerns about 3-in-2 but are now completely on board with the system: it frees up time, making life more flexible both on and off the farm.

Both staff have reduced their hours by 12 hours/fortnight, down to 46 and 43 hours, respectively.

For Karyn and Daryl, there’s more time to pursue off-farm interests, including overseas travel (prior to Covid-19). The change has helped them hit the ‘refresh’ button later in their farming careers.

“As a couple, we’ve always looked to improve how we farm,” says Daryl.

“With overseas markets looking hard at farm animal welfare, people and the environment, 3-in-2 has helped us feel empowered about the changes expected. It’s really ticked all the boxes.”

Now’s the perfect time to check in, plan, and set up for a strong season. We’ve pulled together smart tips and tools to help you stay ahead all winter long.

Whether you prefer to read, listen, or download handy guides, we’ve got you covered with trusted tools to support your journey every step of the way.