Clusters

5 min read

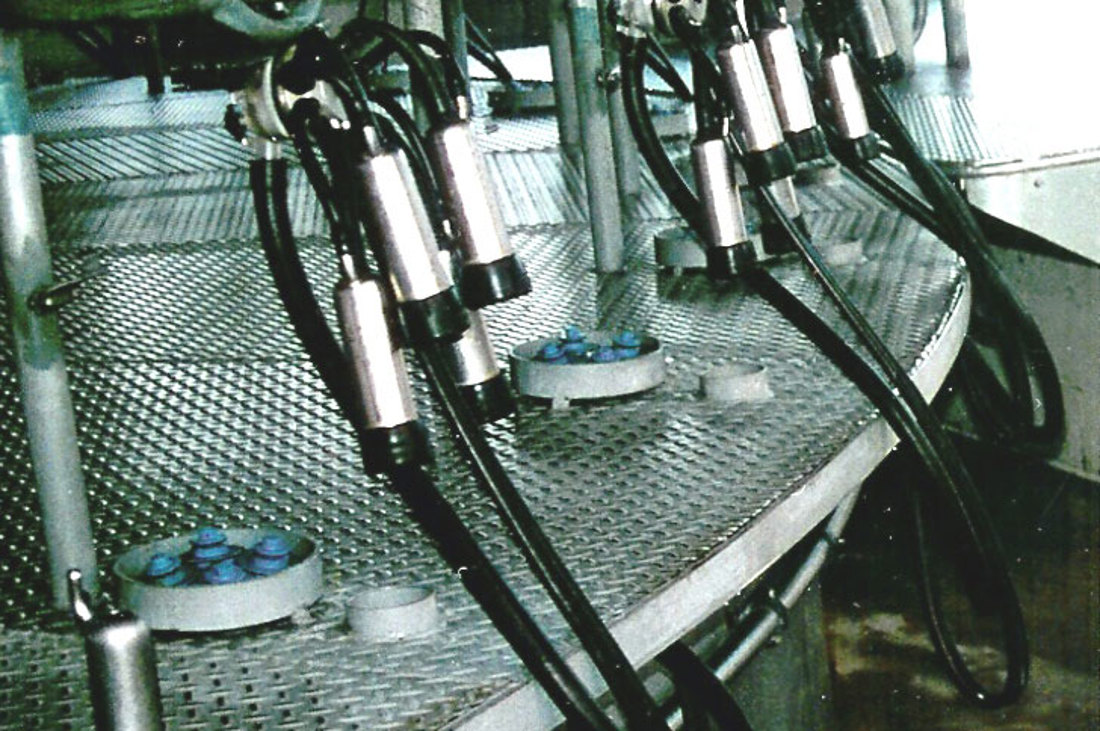

Clusters in dairy milking are a set of components that include a claw and four fully assembled cups. Selecting the right clusters and setting them up correctly will increase milking efficiency and improve animal health. The page explains how to ensure proper alignment, weight, and construction of clusters to prevent issues like teat damage, mastitis, and incomplete milking. It also gives advice on what to consider when buying clusters and how to assess their performance. This information will help you choose the right clusters for your cows, your milking system, and those who are milking them.

Carefully selected clusters that suit the milking system, the cows, and the milkers will help increase milk efficiency and improve animal health.

A complete set of clusters comprises a claw and four fully assembled cups. The components are four sets of teat shells, liners, short milk tubes, short pulse tubes, the long milk tube and long pulse tubing.

Clusters that are correctly set up will be easy to put on and take off and will require no intervention from the milker while a cow is being milked. They will also ensure no cluster slip which can compromise teat health and increase the risk of mastitis.

Ensuring the cow and the cluster are aligned results in a good seal between the teat and liner and is essential for even, fast and complete milking.

If clusters are attached between the back legs, the long milk and pulse tubes must line up with the cow’s backbone, with clusters sitting squarely under the udder.

Poorly aligned clusters.

Well aligned clusters.

Cluster aligning device in a straight rump rail dairy.

In rotaries, poor alignment is a common problem and cows often end up with udders that are lighter on one side as a result.

Consider the following solutions:

Use rubber rings produced by manufacturers – prevents the tube sliding through the hole and pulling the cluster out of alignment

A band of metal welded around the outside of the platform can provide a slot that the milk rubbers are fed through which in turn creates friction to help hold the rubbers in place and improve cluster alignment.

A slot to feed the rubbers through can be included as part of the concrete platform construction. The cluster can align itself with the cow and when not in use pull back out of the way of cows as they exit and enter.

A hook attached to a section of stainless steel tube can be fitted into the long milk tube preventing it from sliding through the hole.

Milk rubbers can be extended to allow them to come over the edge of the platform, rather than through the platform holes. This is possible only if there is a gap between the platform and the entry/exit platform.

The weight of commercially available clusters varies from about 1.6 to 3.5kg. The optimum weight with the commonly used liners in New Zealand tends to be in the range of 2.2–2.6kg.

The main benefit of increasing cluster weight is to reduce the amount of milk (strippings) left in the udder when clusters are removed. However, there are disadvantages of increasing the weight of the cluster including increased milker fatigue, slipping and falling of cups, and teat damage.

The choice of an optimum weight usually involves a compromise, a match based on the cows, the type of liner used, and the preferred vacuum setting.

Cluster weight in relation to the vacuum level

The average vacuum level in the claw during the peak flow period of milking should be within the recommended range of 34-42 kPa.

Note: cluster vacuum is not the same as the working vacuum (as per the vacuum gauge) and requires specialist equipment to measure it.

Long milk tube

Uneven weight distribution between the four quarters of an udder is one of the most common causes of incomplete milking, uneven milk-out, and liner slips.

The milking unit should hang squarely on the udder so that cluster weight is evenly distributed across the udder’s four quarters. This rarely occurs in practice. Usually, the main culprit is the long milk tube, although udder conformation also has a major influence e.g. 3 titters.

Clusters not hanging evenly on the udder can be because the connecting hoses are too long, too short, twisted, or poorly aligned in relation to the cow.

To ensure the long milk tubes are the correct length cut rubbers to roughly the right length and then trim them during milking.

See cluster attachment below in Additional resources for solutions to poor cluster alignment.

Long milk lines can pull the cluster out of alignment.

A mismatch between the claw inlet and the short milk tube (SMT) can cause partial closure of the short milk tube where it joins the claw.

Flattened or kinked SMTs indicate common errors in matching liners and claws. In New Zealand, liner SMT bores vary from 8-14mm with a corresponding variation in claw nipple size. The same liner model is often produced with two different SMT bores to accommodate different claws.

Seek expert help to ensure the liner, SMT and claw are compatible or restriction to milk flow may occur.

The teat cup liner is the only part of the milking machine that comes into contact with the cow's teat, so it heavily influences milking performance as well as udder and teat health. It's therefore important that the liner length is correct for the shell.

Visit the Teat cup liners page for detailed information, see below Additional resources.

Insufficient constriction where the shell meets the short milk tube will allow air leakage. Refer to the Teat cup liners page for more detailed information.

When assessing the ability of clusters to milk out use the following measures:

Incomplete milking: A problem with incomplete milking exists if more than 20% of quarters contain strip yields (milk remaining) of 250ml or more. If there are consistent differences in strip yields between the same quarters on different cows it usually indicates poor cluster positioning or uneven weight distribution between the four cups.

Liner slip: If clusters and milking machinery are satisfactory, liner slips should not exceed more than 5 cows per 100 cows milked (excluding cows with very bad udder conformation).

Most equipment companies will loan demonstration clusters to farmers who are doing an equipment upgrade. This is a good way to evaluate the personal feel and handling characteristics of different clusters as well as their milking performance. You could also visit other farmers who use the same clusters in their dairies.

Studies suggest that claws must have an effective volume of at least 150ml to provide stable vacuum below the teat, minimise crossflow and contamination between quarters, and minimise liner slip.

Other important characteristics of claws include:

Now’s the perfect time to check in, plan, and set up for a strong season. We’ve pulled together smart tips and tools to help you stay ahead all winter long.

Whether you prefer to read, listen, or download handy guides, we’ve got you covered with trusted tools to support your journey every step of the way.