Cleaning your milking system

11 min read

Keeping your milking system clean and safe is an essential part of farm maintenance. The cleanliness of the milking plant and the dairy is critical, so understanding your system and the processes of cleaning is very important. Cleaning must be done properly as bacteria can build up in the plant and contaminate milk. The bacteria affects milk quality by breaking down the components in the milk. This reduces the shelf life of milk and milk products, and produces off flavours in cheeses and milk powders. The New Zealand Food Safety Authority has strict guidelines about dairy plant cleaning procedures to maintain milk quality standards.

Bacteria can enter the plant from cows (teat skin and infected udders) and the environment (drawn into the cluster). The milking environment is ideal for bacterial growth. Effective machine cleaning will control the presence of bacteria in the plant. The quality of the water used is very important in achieving a successful clean.

Water which is too cool leads to redepositing of the milk residues removed, and water which is too hot denatures protein, breaks down detergents, and damages seals and rubberware.

As a minimum the following steps need to be carried out:

Further detail on milk plant and vat cleaning requirements can be found in NZCP1.

Example of an ideal cleaning sequence:

Cold Water Rinse

Hot Water Alkaline / Acid Wash

Alkaline Detergent Wash

Cold Water Acid Wash

Acid Sanitiser Detergent Wash

Typical plant wash programme

| Morning Wash | |||||||

| Mon | Tues | Wed | Thur | Fri | Sat | Sun | |

| Rinse | C | C | C | C | C | C | C |

| Alkaline | H | H | |||||

| Acid Sanitiser | C | H | H | H | C | H | H |

Morning wash - C = Cold wash, H= Hot wash

| Afternoon Wash | |||||||

| Mon | Tues | Wed | Thur | Fri | Sat | Sun | |

| Rinse | C | C | C | C | C | C | C |

| Alkaline | |||||||

| Acid Sanitiser | H | H | H | H | H | H | H |

Afternoon wash - C = Cold wash, H= Hot wash

NB. The alkaline wash should be recycled for 5-7 minutes (if wash water falls to 55°C it should be immediately dumped).

Typical bulk milk tank wash programme

| Mon | Tues | Wed | Thur | Fri | Sat | Sun | |

| Rinse | C | C | C | C | C | C | C |

| Alkaline | H | H | |||||

| Acid Sanitiser | C | H | H | H | C | H | H |

Following milk collection wash - C = Cold wash, H= Hot wash

NB. The alkaline wash should be recycled for 5-7 minutes (if wash water falls to 55°C it should be immediately dumped).

When milk is collected every second day alkaline wash every second pickup.

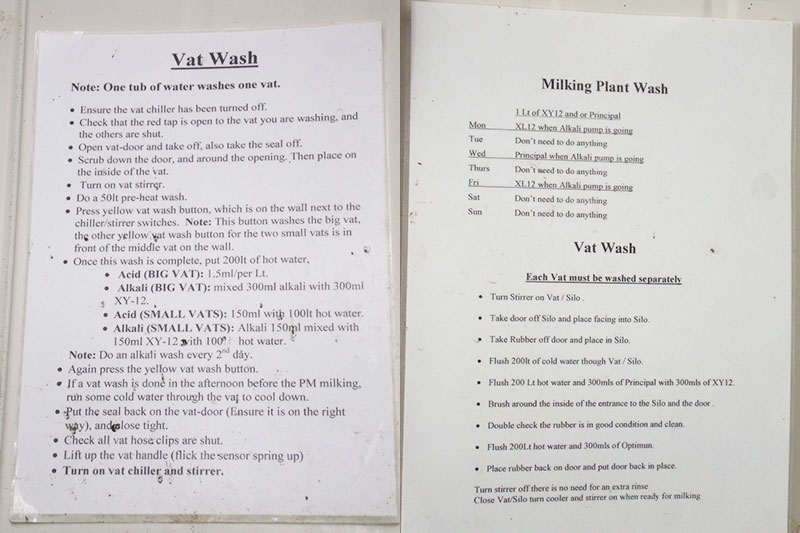

All farm dairies require a written cleaning procedure that is laminated and displayed prominently in the farm dairy. Even if you are the only person working on the farm, there may be a time when someone needs to unexpectedly cover for you.

The procedures must be written clearly so that someone who has never worked in your dairy before can accurately follow the procedure.

General actions to take:

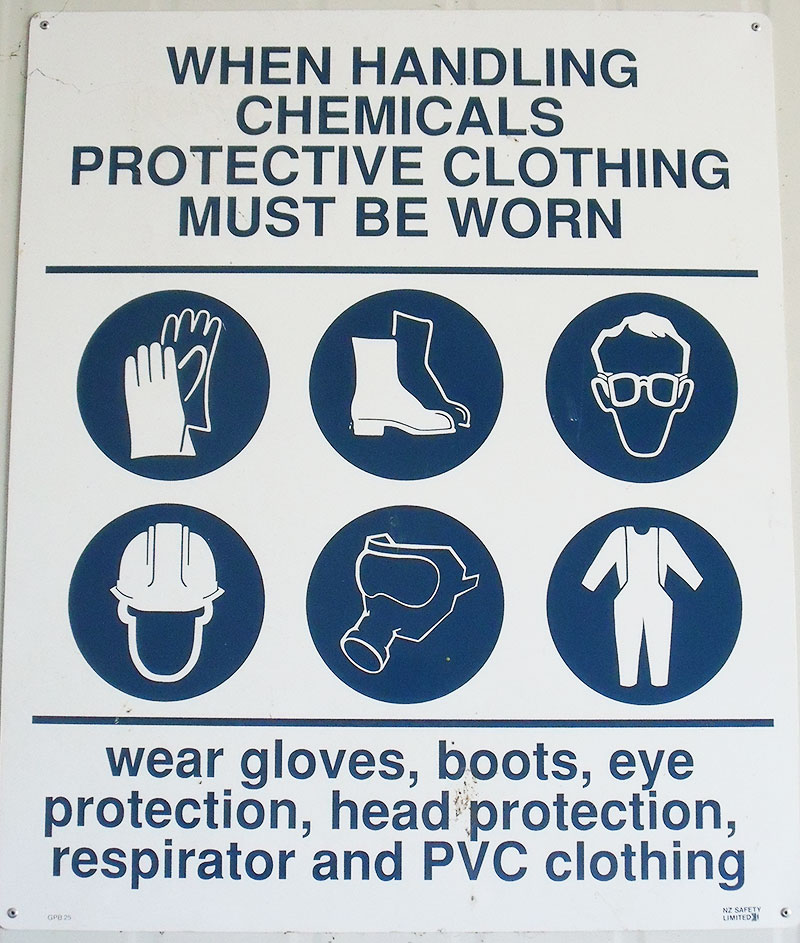

Handling chemicals

Mixing jugs.

Always wear protective clothing when using chemicals including:

Machine cleaning systems maintain milk quality by aiming to remove ALL milk residues from the plant and destroying any resident bacteria.

The benefits of selecting the right cleaning system and following it successfully include:

Automation of the cleaning process can be advantageous as it provides consistency of operation, eliminates human error, and prevents health and safety issues associated with handling strong chemicals and hot water.

If the cleaning process is automated the operator needs to periodically check the automation to ensure the plant is cleaning properly.

An easy-to-operate method of cleaning the pit and milking platform is essential. Some larger dairies are installing automatic washing systems on their milking platforms. This is especially useful if the dairy is used for long periods of time.

Features of a cleaning system

A cleaning system should have the following features:

This type of system is recommended for all dairies.

At the completion of milking, the clusters are connected to ‘jetters’ that are in turn connected to a wash line.

When the milking plant is turned on the vacuum created by the plant draws water from the wash tub through the wash line.

When hot washing, the water should be circulated through the plant for 5-7 minutes, or until it reaches the minimum dump temperature (about 55°C). This is done by connecting a recycle line from the delivery line to the wash tub.

To ensure effective cleaning a minimum water flow of 3 L/min is required through each cluster.

To clean the milk line effectively a flushing pulsator/air injector is normally needed. The flushing pulsator injects air and water into the milk line every 30-45 secs. This injection of water and air creates a turbulent flow of wash water through the milk line which helps to effectively clean the milk line.

| Advantages and disadvantages of circulation cleaning systems | |

| Advantages | Disadvantages |

| Safe to operate - especially if chemical dosing is automated. | Care should be taken if re-circulating the washing solution as it may become too cold and re-deposition may occur. |

| Good contact time and turbulence in cluster. | High initial capital cost. |

| Improved turbulence for large bore milk lines with air injector fitted. | Chemical handling/spillage is possible with non automated systems. |

| Easy to re-circulate wash water to increase contact time and effectiveness of detergents. | Monitoring is required to ensure that all clusters get water, every wash. |

| Easy to automate. | Monitoring to ensure jetter rubberware is not stretched or split - air admission. |

| Advantages and disadvantages of automating circulation cleaning systems |

|

| Advantages | Disadvantages |

| Can eliminate manual handling of chemicals and allow the operator to leave the area while the plant is cleaned. | Not working correctly and going unnoticed by people until demerti milk occurs. |

| Provide consistent operation regardless of operator, providing they are well maintained. | Detergent dispenser not refilled and run empty. |

Reverse flow systems are no longer recommended by the industry for use in New Zealand dairies apart from to rinse the plant with cold water.

In this system, the vacuum pump is switched off and the hose is connected to the milk line between the receiver and the milk pump.

The wash solution is pumped through the hose in to the milk line and passes out through the clusters, flowing in the opposite direction to the normal milk flow.

They have a higher water requirement than other wash systems.

| Advantages and disadvantages of reverse flow cleaning systems | |

| Advantages | Disadvantages |

| Relatively simple to operate. | Expensive to establish, with larger hot water requirements and pumps required. |

| Quick to operate, and no time or energy required for attaching jetters. |

Expensive to run due to high water use and high chemical usage. |

| Quick draining of all milking machine parts. |

Contact wash time very limited. |

| Difficult to automate. | |

| Difficult to perform heavy duty clean if required. | |

| Because liners are not pulsating, they may not be cleaned properly. | |

| Very inefficient use of hot water. | |

| All parts of plant not washed adequately. | |

| Unless well installed can be dangerous to operators. | |

Bucket washing is rarely used now in New Zealand dairies.

In this system the machines are left running and the wash solution is drawn up into the machines via cups from buckets.

The wash solution flows through all of the milk pipes in the same direction as the milk. No special equipment is required except buckets.

This system requires 30 litres of water per cluster per day, and has a high labour component.

| Advantages and disadvantages of bucket washing systems | |

| Advantages | Disadvantages |

| Inexpensive to establish. | High labour cost (if done properly). |

| Very effective results if done properly. | Danger due to carrying of hot water in buckets. |

| Difficult to circulate detergent should a heavy duty clean be needed. | |

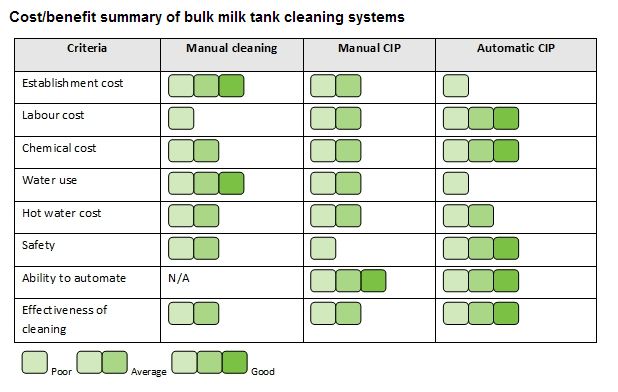

Automation of bulk milk tank cleaning can enable the tank to be cleaned immediately after emptying, reducing the risk of milk residues setting on the tank surfaces, and therefore limiting the opportunity for bacterial growth.

Different methods of cleaning the bulk milk tank require varying labour inputs and offer varying scope for automation.

Manual cleaning involves cleaning of the bulk milk tank using buckets and brushes. It is limited to small lidded tanks as good access to all internal surfaces is needed.

Advantages:

Disadvantages:

Manual CIP involves the fitting of a spray ball or similar device into the top of the bulk milk tank. The spray ball distributes cleaning solutions to all of the internal surfaces. Pump sizes, spray ball design and water volumes need to be matched to provide good cleaning.

Advantages:

Disadvantages:

Advantages:

Disadvantages:

Now’s the perfect time to check in, plan, and set up for a strong season. We’ve pulled together smart tips and tools to help you stay ahead all winter long.

Whether you prefer to read, listen, or download handy guides, we’ve got you covered with trusted tools to support your journey every step of the way.