Flexible Milking, Angela Reid (Northern Southland)

5 min read

Angela Reid manages North South Farms and switched to a 3-in-2 milking routine, a method where cows are milked three times over two days. By trialling this, Angela found it more sustainable, with only a slight dip in production. The shift wasn't easy; the team made numerous adjustments, like changing staff rosters and adapting spring routines. These changes included managing the timing of tasks and altering grazing habits. Despite the challenges, the benefits were clear: improved work-life balance, higher reproduction rates, and a happier workforce. If considering flexible milking, Angela advises commitment, having the right systems, and focusing on the bigger picture.

Angela Reid manages North South Farms, a property under FarmRight management in Northern Southland.

Structure

Corporate

Location

Five Rivers, Southland

Cows

1250 crossbred cows

Farm size

463ha

Production

330kg MS/cow

Irrigation

No

Staff

8 full time equivalents (156 cows/FTE)

Roster

11-3

Milking regime 2020/21

Full season 3-in-2

Pilot farm flexible milking times

Past attempts at switching to OAD late in the season resulted in a loss of production so, in December 2019, Angela Reid and her team trialled 3-in-2 during mid-late lactation as a more sustainable way of reducing time spent milking. Staff were much happier and there wasn’t a big drop in production, so in 2020/21 Angela decided to switch to full season 3-in-2.

It was farm investment manager, Nathan Shirley, who first drew Angela’s attention to DairyNZ’s flexible milking project. Nathan’s enthusiasm, combined with a supportive farm board, gave Angela the confidence to give it a go. But there’s been plenty of fine-tuning along the way; rosters were just the beginning.

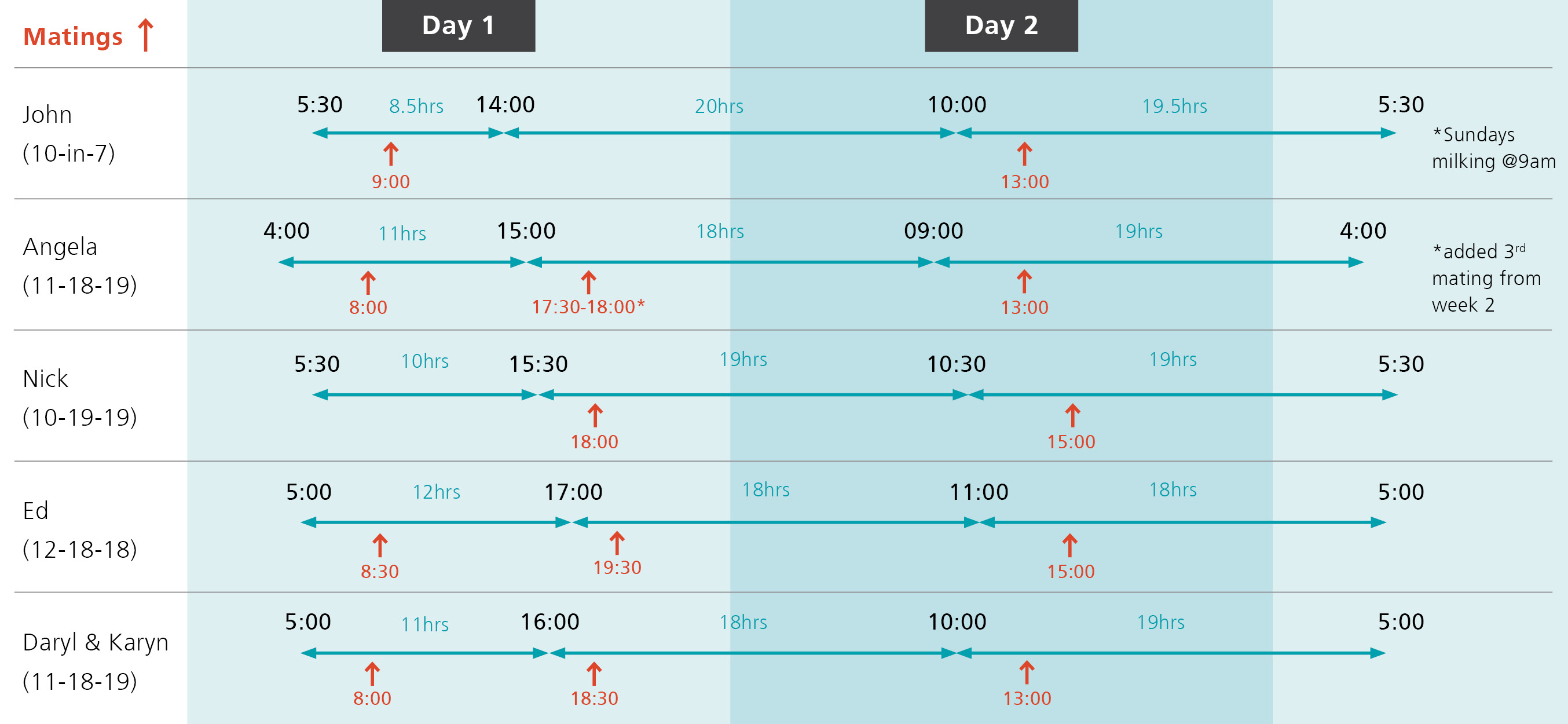

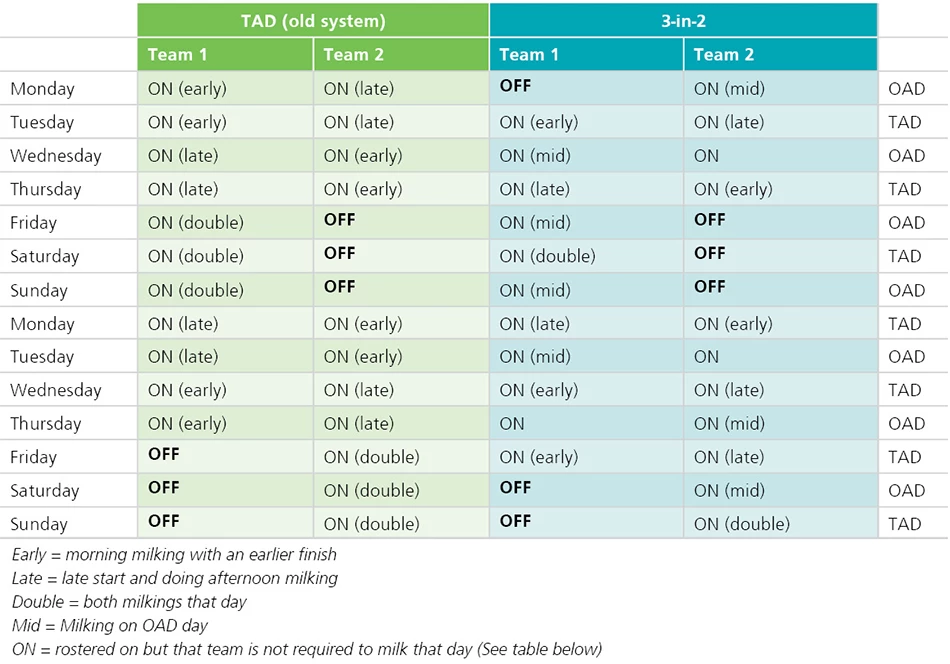

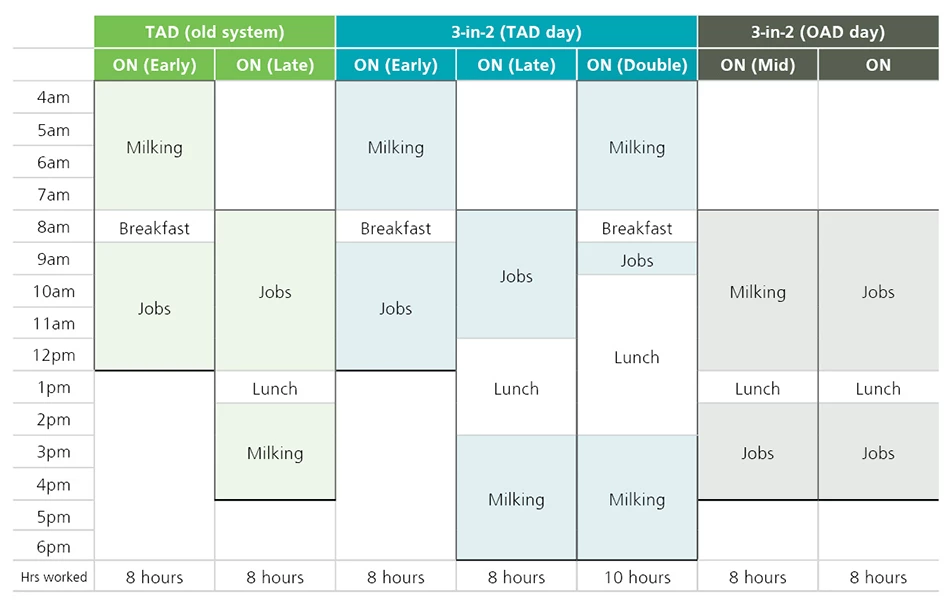

“We have six staff members and we run two teams of three. We asked everyone to decide what they wanted to do as they’re the ones it affects. Rosters started at 6:1 over calving and 11:3 for rest of season. But instead of the usual Friday-Sunday off for both teams, we worked it with the milkings, double milking, single milking, and double milking. So one team got Friday to Sunday off and the other team Saturday to Monday. For the 2021/22 season we changed from the double, single, double milking on the weekends to single, double, single milkings so the team only had to do one early start when we’re running a skeleton crew over the weekends”. See roster below.

Adjustments to drafting springers, mating, and grazing routines was also part of the fine-tuning involved in moving to 3-in-2.

Angela says one of the biggest challenges in making the switch to 3-in-2 was organising the spring routines. “Until we’d got our heads around the timing of what needed to be done and when, they were the hardest things to implement.

It’s all about time management. Improving our milking times helps us to achieve all our outdoor jobs during the spring period. Being prepared and having systems in place to ensure we were maximising our time undertaking the tasks required definitely helped a lot.

Angela Reid

Farm Manager

Spring routines have altered to accommodate bringing springers to the shed for daily drafting.

“In the 2020/21 season, we brought the springers in every second day and drafted them in the paddock on the days they didn’t come to the shed. In 2021/22 we started work at 7am and drafted the springers through the cowshed yards before the 9am milking on the OAD milking days and on TAD milking days the springers came to the shed after the AM milking finished,” says Angela.

Another big change, compared to TAD, has been grazing. Instead of 24-hour grazing, feed allocation has been altered to match milking intervals and is broken down to hourly requirements.

Angela says the cowshed is close to the centre of the farm with three lanes running into it, which allows them to run three herds if necessary and have cows flowing in and out of the cowshed all at the same time.

“We have 104 paddocks all shapes and sizes ranging from 2.08ha to 9.17ha so allocating feed is usually what paddock fits the herds’ requirements that milking.

“We work out the square metres required per day then divide that by 24hrs to get sqm/hour figure then times this by the times between milkings. We have a table that shows us our herd size then the hectares required for 11,18,19-hour feeds and allocate breaks/paddocks to suit the area required,” says Angela.

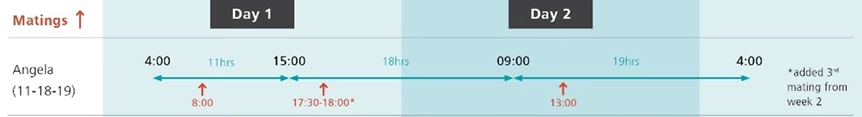

After trying once-a-day mating for a couple of weeks, the team changed to mating at every milking.

“We have a technician from up North who comes to Southland to service a few of our farms and he lives on farm during his time here. We don’t want to miss AI’ing any cows, and in future we will continue with this approach. says Angela.

Figure 2: Milking and mating times used.

One of the biggest successes has been reproduction. Submission rates were up on previous years – the three-week rate was 87.7% vs 72% for the previous year. The percentage of cows calved in the first three weeks of the 2021/2022 season was 60% vs 52% in 2020/21 and in six-weeks 87% versus 81%.

“We’re very happy with the reproduction benefits from full season 3-in-2, but it will be interesting to see what impact it will have on future seasons, says Angela.

| Season: | 2019-2020 | 2019-2020 | 2020-2021 | 2020-2021 | 2021-2022 |

| North-South Farms | Southland average | North-South Farms | Southland average | North-South Farms | |

| Farm milking schedule | TAD, 3-in-2 from Dec |

Part season 3-in-2, 4am:4pm:10am |

Full season 3-in-2, 4am:3pm:9am |

||

| Comments | Provisional numbers only | ||||

| Peak cows milked | 1,237 | 644 | 1,250 | 662 | 1,180 |

| kgMS/cow | 359 | 460 | 326 | 449 | 340 |

| kgMS/ha | 1,068 | 1,348 | 981 | 1,241 | 963 |

| 10-day peak milk per cow (kgMS/cow/day) | 1.84 | 2.07 | 1.64 | 2.06 | 1.76 |

| Imported feed (kgDM/cow) | 0 (for milking) | 780 | 0 (for milking) | 698 | 138 |

| kgN applied/ha | 34 | 191 | 34 | 147 | 46 |

| 6wk ICR | Not recorded | 74% | Not recorded% | 69% | 67% |

| Not-in-calf rate | 18% | 12% | 11% | 13% | 14% |

| FWE ($/kgMS) | $3.70 | $4.61 | $4.20 | $4.84 | $4.90 |

| Profit/ha | $3,244 | $3,027 | $3,266 | $3,203 | $4,328 |

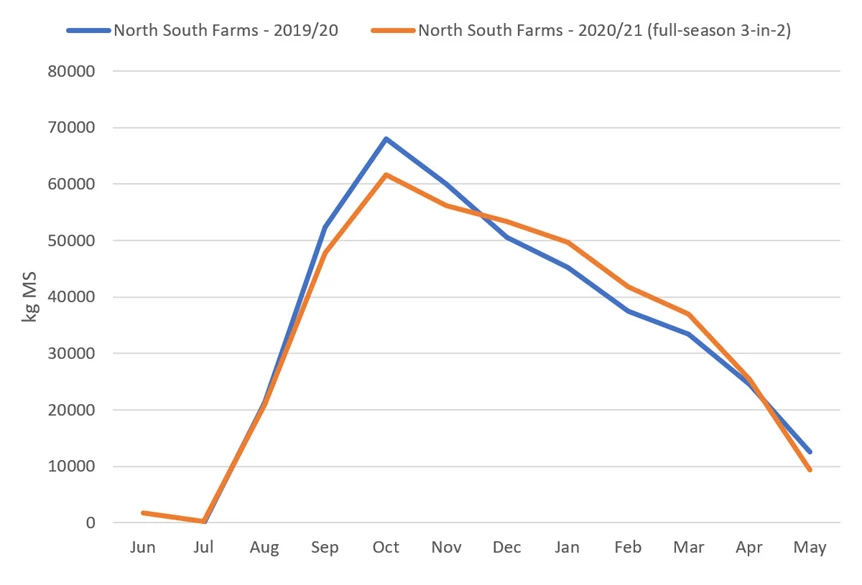

“Staff are happier at work and well-rested. They have only four early starts a fortnight instead of seven when they milked TAD. Animal health has benefited too, with Body Condition Score being consistent for most of the season. Production didn’t peak as it normally would have but held for longer (see graph below) and didn’t drop the same as it would have on TAD and then going to OAD.”

“Production in our second 3-in-2 season to date has pretty much mirrored the first, but we calved 100 less cows than last season and the cows peaked higher than the first 3-in-2 season.”

Adopting flexible milking has allowed Angela to take a new approach to improving work hours and work-life balance for herself and her staff.

If you’re considering flexible milking Angela says:

“Go for it and enjoy the journey. There will be ups and downs along the way but if you have good staff, the right systems in place and can look at the bigger picture then you and your staff will love it.”

Now’s the perfect time to check in, plan, and set up for a strong season. We’ve pulled together smart tips and tools to help you stay ahead all winter long.

Whether you prefer to read, listen, or download handy guides, we’ve got you covered with trusted tools to support your journey every step of the way.